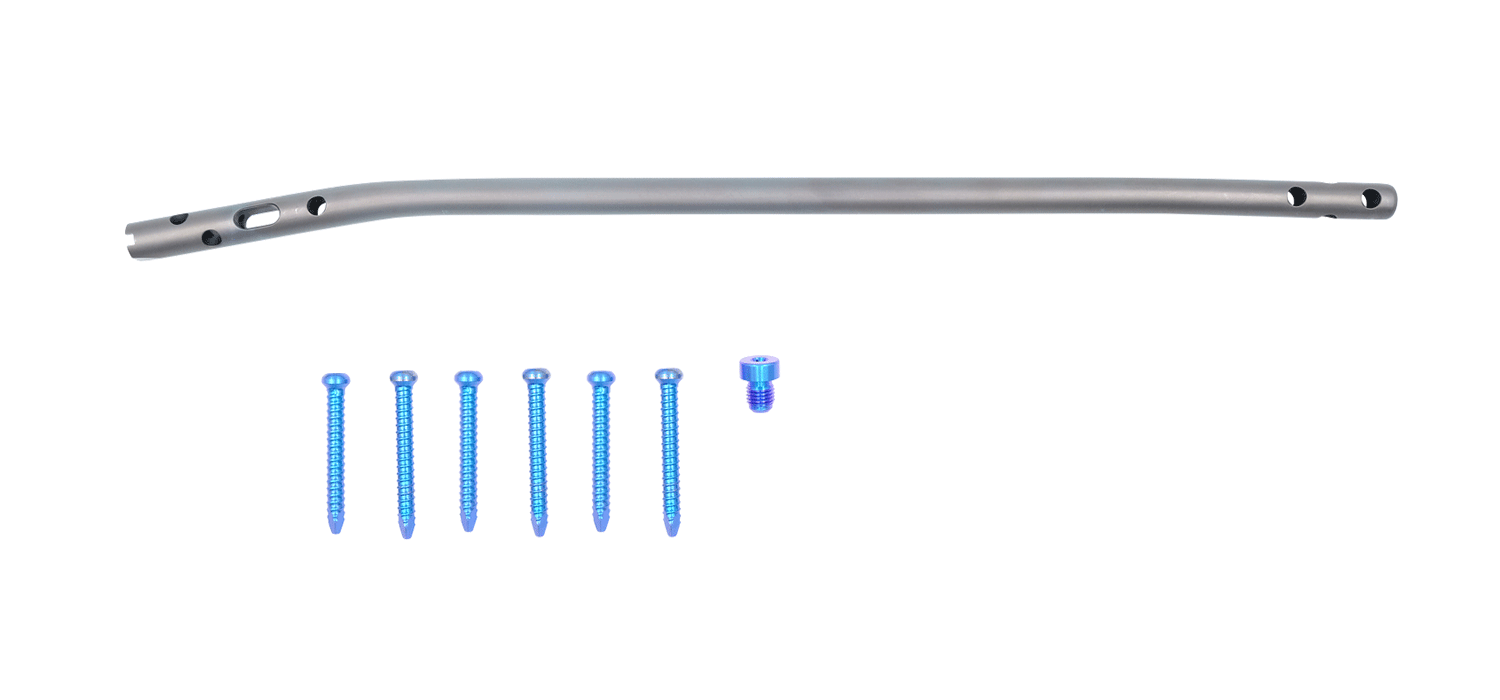

Tibia Intramedullary Nail System

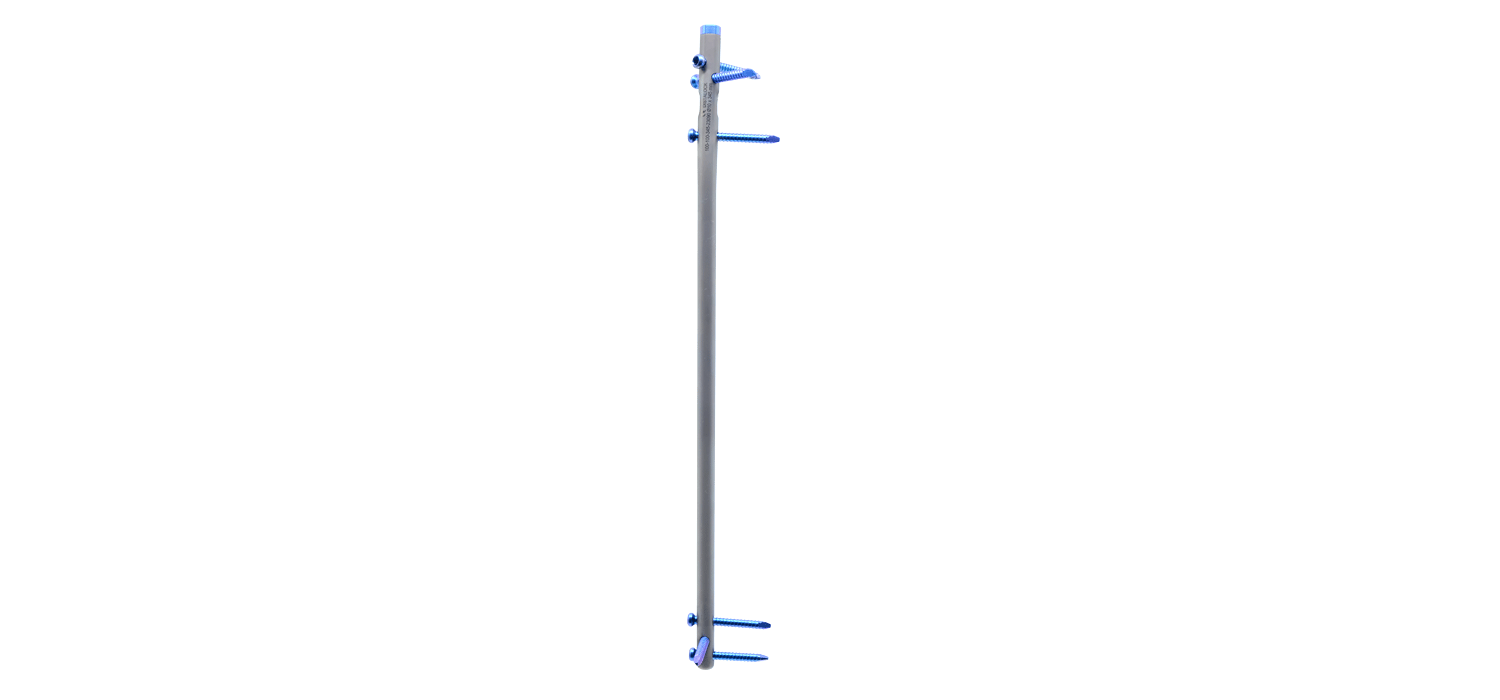

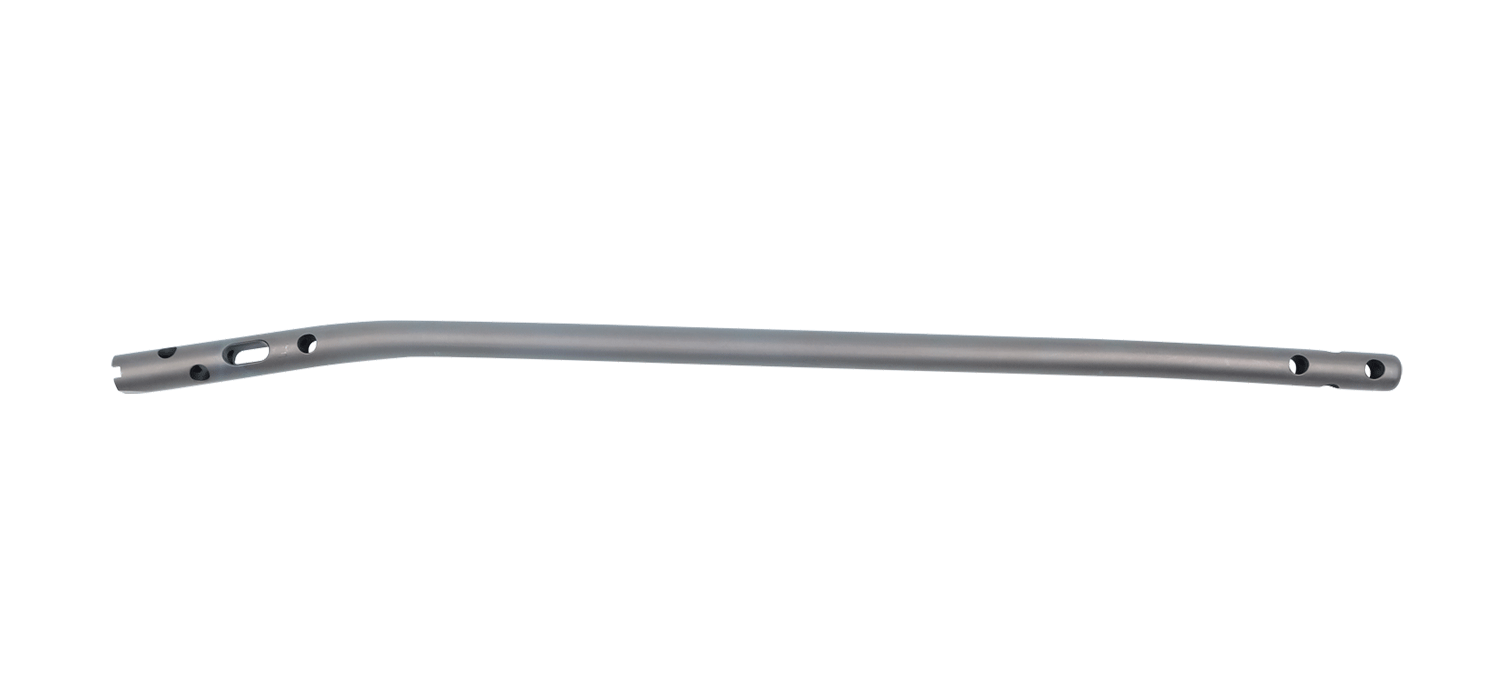

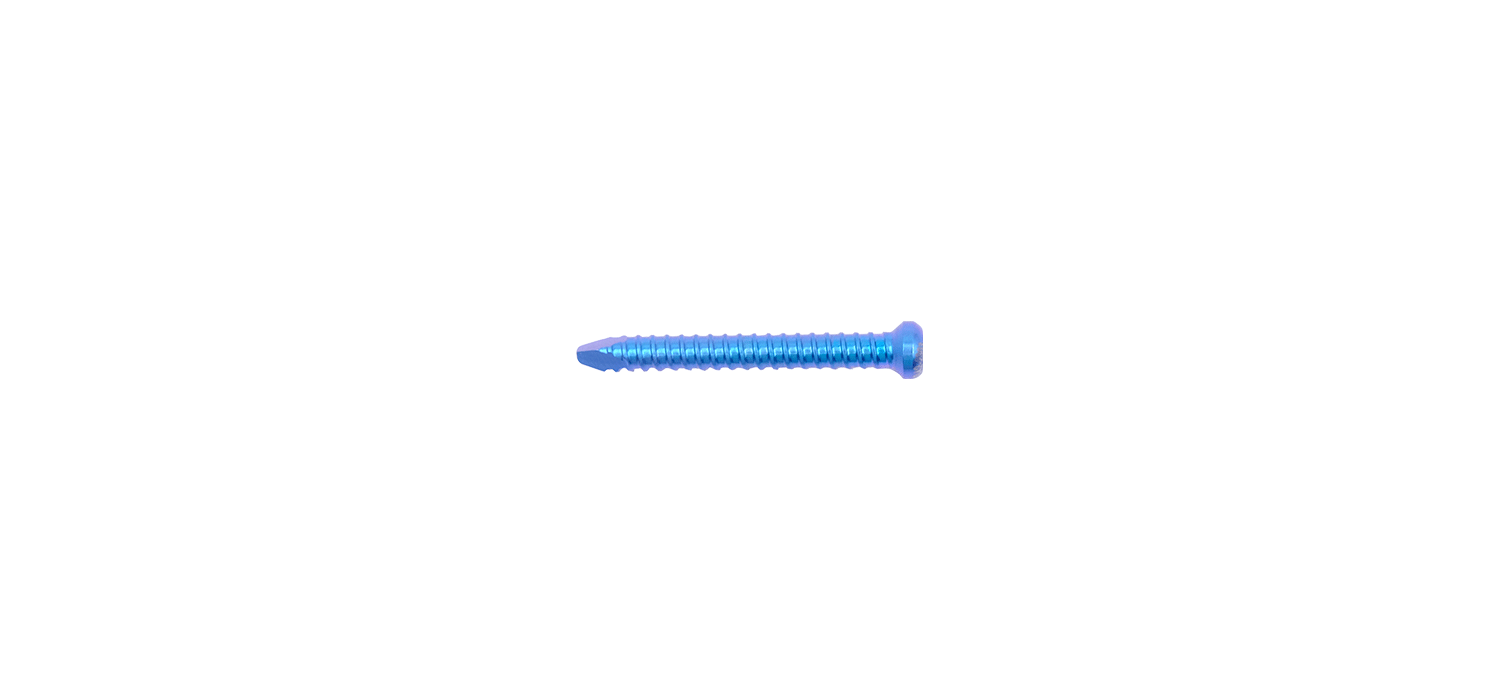

Tibial Intramedullary Nails: They are used in proximal, distal, and shaft fractures of

the tibia bone. It has a cannulated and circular cross-section with curves, featuring 3

distal and 4 proximal holes through which the locking screws pass. The Tibia

Intramedullary Nail has a 10° proximal offset angle and a 3° distal offset angle. The 3

distal holes are for static locking only. One of the 4 proximal holes is a slot designed

for either dynamic or static locking.

| Ürün Adı | Tibia Intramedullary Nails; |

| Ürün Tanımı | It is a structure with bends, featuring a cannulated, circular cross-section and three distal holes for locking screws and four proximal holes. |

| Ürün Kullanım Amacı | The Tibia Intramedullary System has a proximal bend of 10° and a distal bend of 3°. |

| Endikasyonlar | Tibia intramedullary nails come in various lengths. |

| Kontraendikasyonlar | They come in lengths ranging from 255mm to 420mm, increasing in 15mm increments. |

| Hasta Popülasyonları | These lengths are available in each diameter of 9mm, 10mm, and 11mm |

| Ürün Komplikasyonları | The 3 distal holes are for static locking only. |

| Temas Edebileceği Organlar | One of the proximal holes is rectangular in shape, which is intended for dynamic locking. |

| Vücutla Temas Süresi | There is a female thread at the proximal end of the nail. This is provided for the implantation and removal of the nail. |

| Sterilite | Additionally, this female thread is for the peak screw socket. |